Mosin Nagant M91/30 Rifle Restoration

by Kevin Wilson

by Kevin Wilson

Restoration goals, expectations, disclaimer.

Cosmoline, rust, etc.

How to safely disassemble your Mosin.

How to clean and polish the bolt.

How to refinish the stock.

How to blue the metal bits.

Helpful links, contact info.

This guide will document the process I used to restore and refinish a Mosin Nagant M91/30 rifle. This is the first Mosin I've restored, so I'm not an expert and I can't compare all the possible restoration techniques. Your process and results may vary.

Before you start refinishing, you should decide what you want your rifle to look like. A new modern rifle? Like it came off the Russian assembly line 70 years ago? Or just cleaned up and ready for the range? This will help determine how much time, effort and money you'll need to put into the project. Some people consider Mosin Nagants historical artifacts, and frown upon anything more than minimal preservation. Other people consider them old, surplus military rifles and despite a lot of historical significance, they're just a rifle with only one purpose - to blow holes in stuff. I made no effort to preserve the historic condition of my Mosin.

Before I saw the rifle, I had planned to restore it to the same condition as a typical new rifle. After I saw the rifle, I knew that wasn't going to happen. This rifle looked like it was made in a high school metal shop class, then taken out and beaten with an ugly stick by half the Russian army. There wasn't any area on the rifle without machining marks, pitting, dings, and all sorts of other imperfections. It may have been possible to remove all the imperfections, but it would take far more time and effort than I was willing to invest. I ultimately decided to spend some time cleaning it up and looking presentable on the range, but not perfect. Any remaining imperfection would be considered "character".

I am not a gunsmith. I am not responsible if you break something or injure someone.

Cosmoline... Is your rifle covered in it? If so, you'll have to remove it. You can use either heat or a solvent to remove cosmoline. Everyone has a different method, but I recommend washing it off with a solvent, like mineral spirits. Other people use break cleaner, oven cleaner, steam, boiling water, heat from the sun or various other things. Using mineral spirits is fairly simple, just go get a big can of mineral spirits, a big plastic tub and a nylon brush. Be sure to do this in a well ventilated area with gloves. You'll probable need to disassemble the bolt to get it clean (see below). Also, be sure to oil all metal as soon as the solvent has evaporated to prevent rust.

I had a hard time getting my barrel clean. You don't have to clean the barrel to restore your Mosin, but it'll probably help to prevent contamination during the bluing process. I suspect the corrosive primers and lack of through cleaning left some pitting in the barrel that increased the surface area and gave the fouling lots of places to accumulate. I don't have any magic tricks to clean the barrel in 10 seconds. A bore snake seemed to speed up the process.

This will be a brief overview of Mosin Nagant M91/30 disassembly. There are many resources online if you need more detailed directions.

First, inspect the chamber and make sure the rifle is not loaded. Follow all safety rules when disassembling the rifle. Don't nominate yourself for a Darwin Award.

Some people remove the recoil bolts before refinishing the stock. Other people (including myself) just work around the bolts. If you decide to remove them, it's easier to do it before disassembling the rest of the rifle. Use a pair of snap ring pliers to unscrew the bolts. You may need to carefully tap them out of the stock.

I recommend keeping all the screws and small parts in a zip-loc bag.

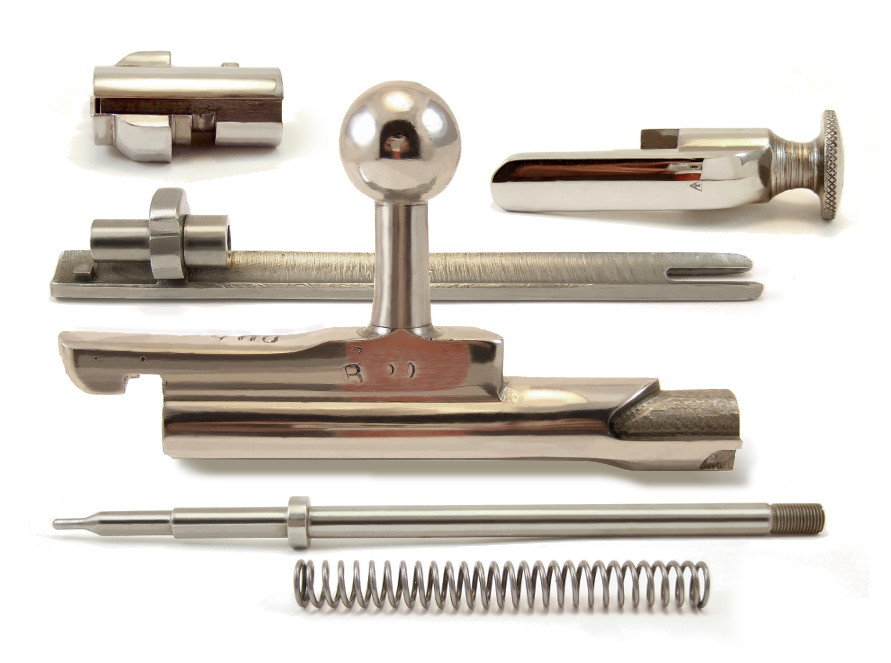

Bolt Head, Cocking Knob, Guide Rod, Bolt Body, Firing Pin, Firing Pin Spring

There's two reasons to sand / polish the bolt; form and function. Parts of the bolt can be polished to a beautiful mirror finish. Other parts can be sanded smooth to improve the operation of the bolt.

According to tnekkc, polishing the contact areas in the bolt and trigger will not significantly reduce the required trigger pull force. Polishing may smooth the trigger pull, but his studies show that the sear spring is the only significant factor affecting the trigger pull.

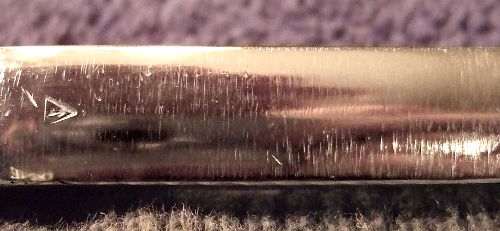

Fairly rough surface. Start with 400 - 600 grit.

Before you start sanding, it's important not to sand any surface that's critical to the proper and safe operation of the rifle. Don't mess with the bolt face, the end of the firing pin or the extractor. Don't sand the spring (unless you want to reduce it's strength). Don't change the shape or size of anything. Don't round off the edges (unless they're really sharp).

Good, but needs more work. Start with 800 - 1000 grit.

The bolt disassembly process isn't very difficult, but there are several good video tutorials on the internet that can explain it better than the following directions...

You have two methods to complete the bolt disassembly:

Option 1:

Option 2:

There are many things that can cause the bolt to be stiff, usually it's hardened cosmoline or a burr in the chamber. Sanding the bolt cam surfaces smooth will probably not make a significant difference - unless the surfaces are very rough. If you still want to improve the operation of the bolt by sanding and polishing, just look for the places on the bolt and receiver that rub together and make sure they're smooth. Don't sand too much and only use 1000 grit sandpaper or higher on these areas. The surfaces do not need to be perfectly smooth.

As an alternative to sanding and polishing, some people put polishing compound on the cam surfaces and open/close the bolt 1000 times, but using a Dremel with a polishing wheel produces the same results in about 10 seconds.

Almost a mirror finish. Start with 2000 grit and polishing compound.

Polishing is a process that can require quite a bit of time and patience. I use 400 to 2000 grit wet/dry sandpaper and a Dremel with polishing compound.

First, evaluate the surface. If the scratches, machine marks, pitting, etc. are deep, then start with 400 to 800 grit sandpaper. If the surface is in fairly good condition, start with about 1000 grit sandpaper. Sand with oil to prevent the sandpaper from loading up (accumulating a thick layer of metallic dust on the surface of the sandpaper). Use light pressure until all the existing scratches are gone and the surface has an even finish. Move up to a finer grit and repeat. Generally, you should double the grit when you move up. After 1500 to 2000 grit sandpaper, move to the Dremel and polishing compound. If scratches persist, drop back to the sandpaper then re-polish.

A mirror finish.

If you plan to use your Mosin from a concealed position, you probably won't want to polish the bolt and create a reflective surface. In this case you can create a nice, non-reflective finish by finishing the surfaces with 600 to 1000 grit wet/dry sandpaper or a green kitchen scrubbing pad.

For more polishing information, refer to my revolver polishing guide.

The stock seemed to be in average condition. I decided to completely strip the stock, stain it and finish with polyurethane. Of course, there are many other ways to refinish a Mosin stick, but this method seems to be very easy and produce good results. I didn't remove the barrel band springs, cross bolt / recoil bolt or sling escutcheons. I just stained and polyurethaned right over them.

Original condition.

Original condition (alternate view).

The stock was covered with a thick layer of old shellac. Shellac can be repaired fairly easily, but I wanted a tougher finish. I started with 90% rubbing alcohol and green scrubbing pads. It was removing the shellac, but after 20 minutes of scrubbing there was still quite a bit of shellac remaining. I ran to the hardware store and found some Zinsser Furniture Refinisher. The can says it "Gently dissolves old finishes - preserves woods original color and character." It worked 10 times faster than rubbing alcohol and did not damage the wood, but the fumes were terrible! According to the MSDS it contains acetone, methanol and toluene. If you use any of these solvents, I strongly recommend wearing gloves and stripping the stock outside.

After stripping the shellac and de-greasing.

The wood was oily after stripping off the shellac. I suspect the cosmoline had saturated deep into the wood. I sprayed it down with some commercial de-greaser, let it soak for a minute then rinsed with rubbing alcohol. I repeatedly de-greased and rinsed a few times. That seemed to remove most of the cosmoline without harming the wood. You can also let the stock sit in the hot sun and wipe off the cosmoline as it seeps out every half an hour. This method may take several days.

But now the wood seemed too dark and dingy. I mixed some OxiClean with water (it wouldn't dissolve in rubbing alcohol) and poured it on the stock. After letting it sit for 20 minutes I rinsed it off. After repeating a couple times the wood seemed to lighten a bit, but it didn't look like new, unfinished wood. Maybe next time I'll try some liquid bleach.

After bleaching with OxiClean.

This is the time to repair any dents in the stock. They can be steamed out with a wet cloth and an iron. The process causes the wood fibers to swell up, hopefully returning to their original shape and resulting in a smooth surface. First, apply some water to the dent and let it soak in for a while. Apply more water until the dent is saturated. Next, wet a cloth or towel. Lay it on the dent and use a hot clothes iron to steam the wood. Hopefully the dent will smooth out. You might have to steam it several times. Gouges can be filled with wood filler.

It's usually easier to achieve a smooth, gloss finish if you fill the pores. Mosin stocks are usually made of birch, which has fairly small pores. Filling the pores probably won't do much good. I never bother with it, but if you want to invest some time doing it now, you might save a little time later sanding the finish smooth.

After letting the stock dry completely I sanded with 320 grit to knock down the grain that was raised with the OxiClean bleaching. I cleaned off the sanding dust, hung it and applied a thick coat of Varathane light cherry stain. I waited about 5 minutes and hit it again. After about 15 minutes I wiped off the excess. The wood didn't seem to absorb much stain. The new color came out very close to the original color (before any work was started on the stock).

After staining.

I decided to finish with polyurethane. Some people may feel that shellac is more appropriate for a Mosin, but polyurethane is easier to apply and much more resistant to solvents, water, abrasion and pretty much everything else. You can apply a sealer to hold in the cosmoline, but it doesn't seem to be necessary. Update... It's been 3 years and the polyurethane looks fine (no separation, peeling, cosmoline seeping or anything).

You'll need to choose between a gloss or satin finish. I recommend a satin finish because I think it just suites the character of the rifle better and a gloss finish will highlight every dent and gouge in the stock. You can always change your mind and put a gloss finish over a satin finish later. You can also apply a gloss finish and buff it to a nice satin finish with 0000 steel wool or a 3M brand synthetic steel wool pad.

I generally apply a very thin coat of wipe-on polyurethane on every surface, inside and out. This seals the wood to protect from water, oil, etc. I apply the poly using a paper towel folded to about 1" x 3". Old t-shirts and socks also work really well.

Dying and staining both color the wood, but dye will allow more of the grain to show through. My stock didn't have much grain, so dying wouldn't be much better than staining. If you decide to dye the wood, I recommend Rit cloth dye. There are more expensive dyes made specifically for wood that can produce better results, but cloth dye is cheap and easily available. For a Mosin, I'd recommend mixing 50% red and 50% brown dye. If possible, test it in an inconspicuous place on the stock. I mix the dye with about equal parts distiller water in an old glass jar. Because the dye is water based, it will raise the grain. It requires an extra sanding step to remove the raised grain, but the result is slightly smoother than if the grain had not been raised and sanded down.

Applying wipe-on poly is almost foolproof, but there's a couple things that can mess it up. The temperature should be above 60 degrees F, otherwise the poly will take several days to dry (during which time it will collect a lot of dust). If temperatures get above 90 or the humidity falls under about 30% then the poly can dry so fast that it becomes difficult to apply. The poly needs to dry in an area that does not have dust or drafts. Any dust that lands on the poly before it's dry will become embedded - and that makes it difficult to get a nice, smooth finish. The poly is going to smell a little funny for a few days as it dries.

You should follow the directions for whatever finish you use. Here's my general finishing process. I know it looks like a lot of steps, but each step is easy and the results are almost guaranteed to be beautiful...

It'll generally take at least 2 coats, usually 3 or 4, rarely more. This should result in a very smooth and beautiful finish.

Completed semi-gloss finish.

Watco danish oil can create a fairly good finish. It's very easy to apply, just wipe on, let it sit for about 10 minutes and wipe off the excess. A couple coats is all you need and it results in a natural looking finish. Unfortunately, it only provides minimal protection.

The shellac finish can be restored. Sometimes all you need to do is clean the finish. If cleaning isn't enough then you can wipe down the surface with alcohol to partially dissolve it and polish it to a nice, new condition. If that doesn't work you can apply a new layer of shellac. I won't go into the details of how to do all of that because it could turn into it's own guide. There's some good instructions on the internet.

You can use many other finishes, but keep in mind the stock will likely get wet from washing out the barrel or maybe rain, it'll be exposed to various cleaning solvents and it'll probably get a little beat up through normal use - so choose your finish appropriately.

I don't think it's possible to achieve great results at home. I've tried several times and the best I can manage is a good result - but definitely not professional quality. Maybe it's just me. Of course you can send it off to a pro - but that'll probably cost as much as the Mosin. If your Mosin has a decent finish on it, I'd recommend leaving it alone. It's probably not worth the hassle.

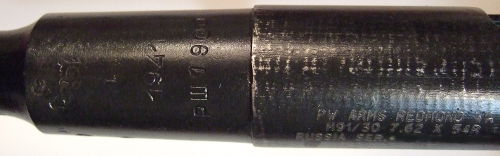

Original condition.

You'll need to sand off the old finish and smooth the surface. Don't sand too much on any surfaces that contact the bolt or stock, or will affect the operation of the rifle. Start with a Dremel and a "rubber polishing point" to smooth out any rough spots. Next, use 400 - 600 grit wet/dry sandpaper and oil. Sand until the entire surface is clean and smooth. The surfaces on my Mosin were so full of machine marks and dents that they were impossible to completely sand out. Switch to 1000 grit wet/dry sandpaper and oil. If you want a nicer finish you can move onto 1500 - 2000 grit wet/dry sandpaper and oil. If you want an even nicer finish you can use the Dremel polishing wheel with polishing compound.

Original condition (left) and after sanding (right).

Machine marks remain after a lot of sanding.

I won't cover my bluing procedure because the bluing you use may require a different procedure, but I'll offer some helpful tips.

First, work as fast as possible. The first step is to strip all the oil off the metal and rinse with water. The metal will begin to rust immediately. The faster you work, the less rust you'll have. Because time is a factor, you may want to only blue half the rifle at a time. Make sure the metal is absolutely clean before applying the bluing. Wear gloves to prevent fingerprints in the finish. Rinse the metal with very hot water. Bluing seems to work better on hot metal. If you've never blued, practice the entire procedure on a small piece first. A barrel band or the butt plate makes good test subjects. You'll probably have to repeat the bluing and rinsing process a few times to get a nice, dark blue finish. Soak the metal in oil as soon as you finish the bluing process.

After bluing.

Lack of bluing around the edges.

You can paint your Mosin. Any good quality spray paint that's recommended for metal should work fine. Strip all the oil out of the metal. Rubbing alcohol is probably the easiest and cheapest way. Use tape to mask anything you don't want to paint (like inside the chamber and barrel), and spray on a thin coat, let dry and repeat several times.

62x54r.net - A Mosin Nagant Reference

mosinnagant.net - The Homepage For Mosin Nagant Rifles And Collectors.

wikipedia.org - The Mosin-Nagant encyclopedia page.

8541tactical.com - Tactical Rifle Painting by John McQuay.

americanrifleman.org - Camouflaging Your Gun by Cameron Hopkins.

You may also be interested in my revolver polishing guide, my custom Ruger SP101 wood grip guide, rifle round reloading guide or my other pages.

You may contact me at kevin@kevinsworkbench.com